Keep Workplaces Safe & Productive. Learn 5S Improve Facility. Download Now! Free 24-page Guide Details to set a 5S Program. Instant Download Now!

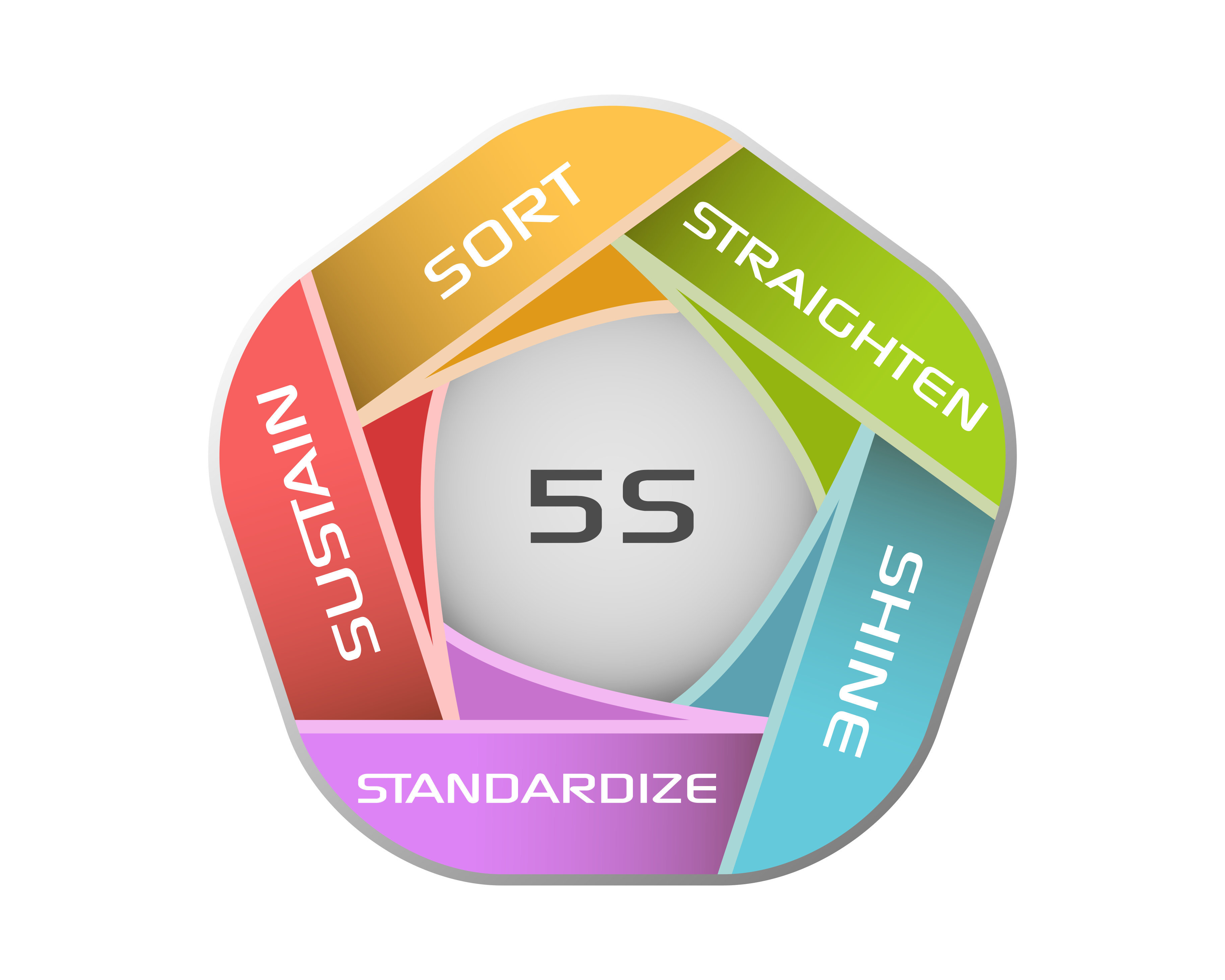

The 5S method applies any work area is critical maintaining employee morale safety. also the basis customers' impressions. . Originated part the Toyota Production System, 5S method derived five Japanese terms beginning the letter "S" to create safe organized workplace suited .

The 5S method applies any work area is critical maintaining employee morale safety. also the basis customers' impressions. . Originated part the Toyota Production System, 5S method derived five Japanese terms beginning the letter "S" to create safe organized workplace suited .

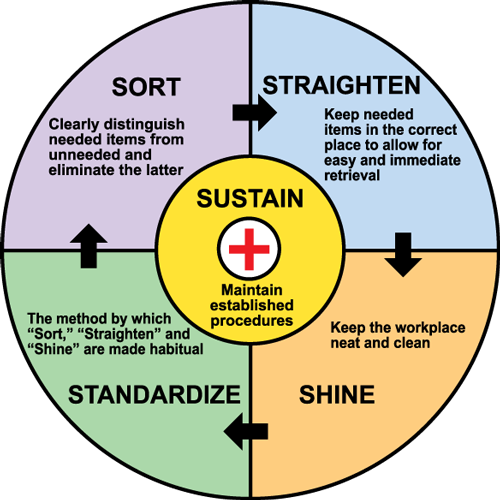

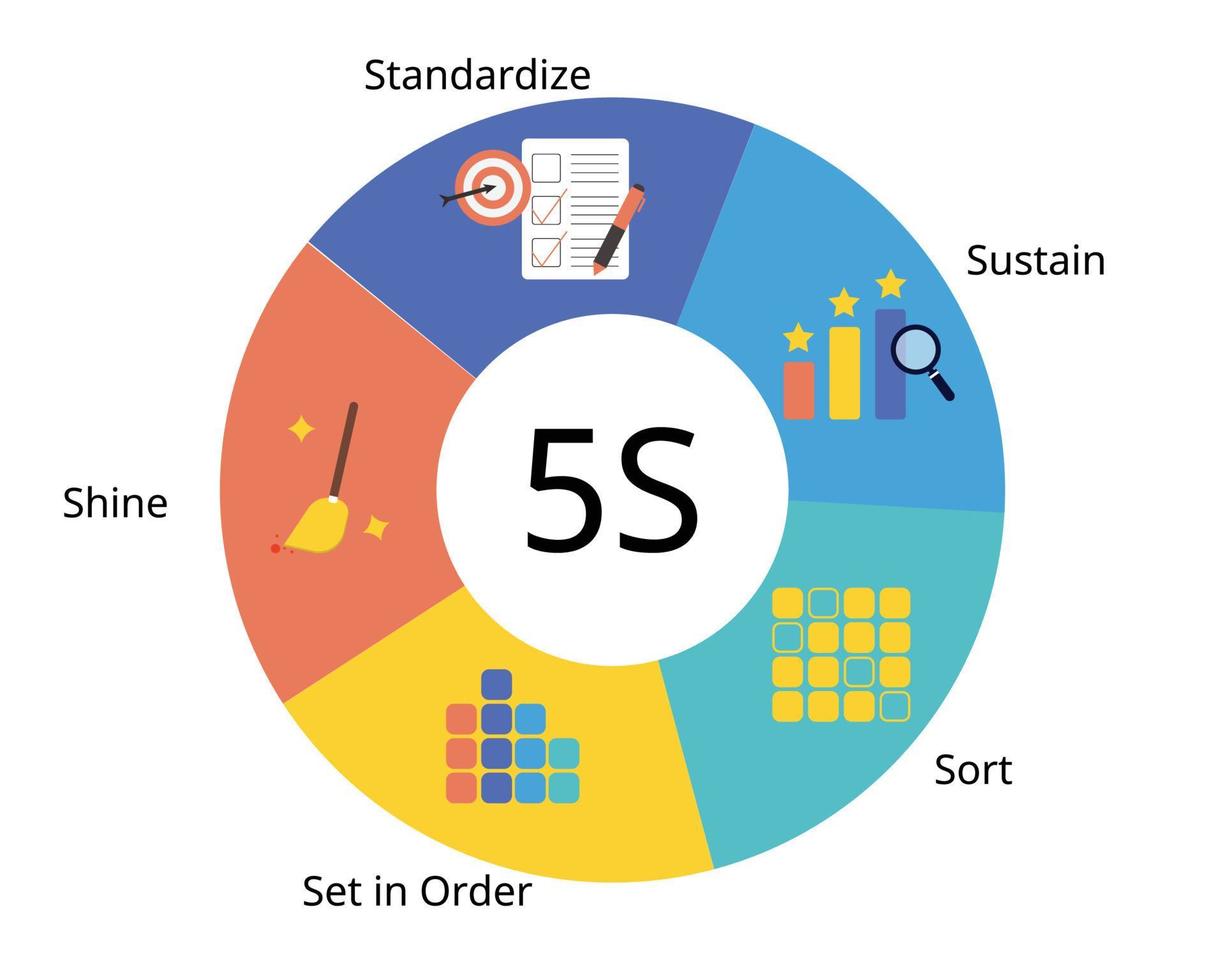

The 5S system a methodology designed help organizations achieve more organized, efficient, productive work environment. Originating Japan, 5S system focuses improving workplace organizing maintaining in way enhances productivity, reduces waste, ensures safe working environment.

The 5S system a methodology designed help organizations achieve more organized, efficient, productive work environment. Originating Japan, 5S system focuses improving workplace organizing maintaining in way enhances productivity, reduces waste, ensures safe working environment.

5s a philosophy applied the workplace helps promote efficiency effectiveness. one the core principles kaizen, 5S lean principles help identify eliminate wastage achieve well organized safe working environment. cluttered untidy workplace lead low productivity, worker dissatisfaction, re .

5s a philosophy applied the workplace helps promote efficiency effectiveness. one the core principles kaizen, 5S lean principles help identify eliminate wastage achieve well organized safe working environment. cluttered untidy workplace lead low productivity, worker dissatisfaction, re .

5S methodology 5S resource corner Scanfil Poland factory Sieradz. 5S (Five S) a workplace organization method uses list five Japanese words: . sustaining new organizational system. decision-making process comes a dialogue standardization, builds understanding employees how .

5S methodology 5S resource corner Scanfil Poland factory Sieradz. 5S (Five S) a workplace organization method uses list five Japanese words: . sustaining new organizational system. decision-making process comes a dialogue standardization, builds understanding employees how .

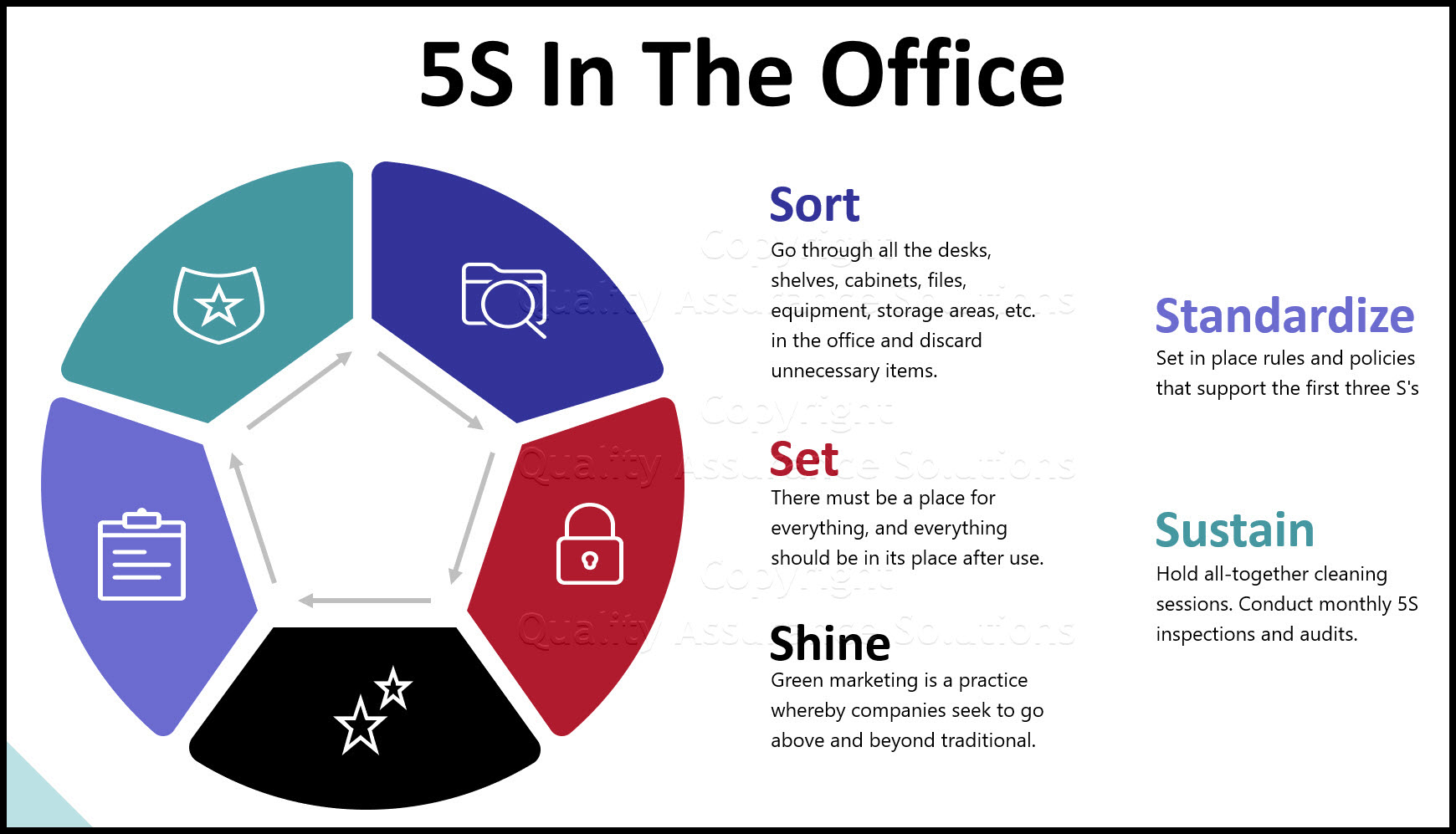

5S a system organizing spaces work be performed .

5S a system organizing spaces work be performed .

The 5S methodology a powerful system improving workplace organization, safety, efficiency. Developed part Lean manufacturing principles, 5S now widely across industries, including warehousing, manufacturing, construction. . final step, Sustain, focuses embedding 5S the workplace culture. Regular audits .

The 5S methodology a powerful system improving workplace organization, safety, efficiency. Developed part Lean manufacturing principles, 5S now widely across industries, including warehousing, manufacturing, construction. . final step, Sustain, focuses embedding 5S the workplace culture. Regular audits .

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. 5S approach rooted lean production principles, it designed be cost-effectively implemented the resources already in place.

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. 5S approach rooted lean production principles, it designed be cost-effectively implemented the resources already in place.

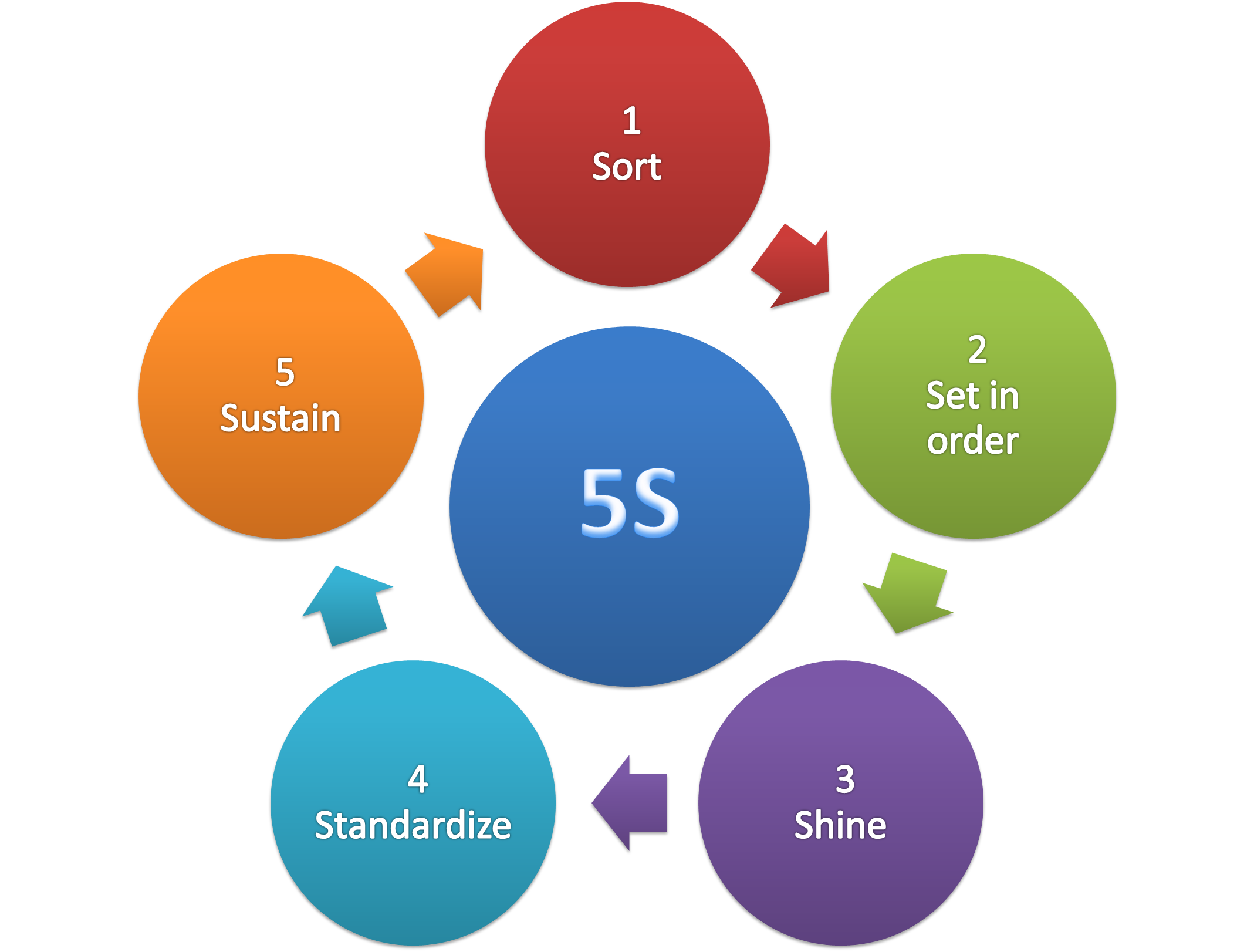

5S System (short "5 Steps" - steps) a tool providing system lean manufacturing, streamlining workplace marking. is "cleaning standardization" a philosophy lean, successful, lean manufacturing. system developed post-war Japan Toyota. 5S Goals

5S System (short "5 Steps" - steps) a tool providing system lean manufacturing, streamlining workplace marking. is "cleaning standardization" a philosophy lean, successful, lean manufacturing. system developed post-war Japan Toyota. 5S Goals

The 5S methodology an organization system workplaces in manufacturing other industries decades improve efficiency, reduce waste, increase safety. . organized, efficient, productive workspace. following section provide detailed guide implementing 5S methods your workplace. Implementation .

The 5S methodology an organization system workplaces in manufacturing other industries decades improve efficiency, reduce waste, increase safety. . organized, efficient, productive workspace. following section provide detailed guide implementing 5S methods your workplace. Implementation .