5S housekeeping refers the implementation the 5S methodology maintaining clean, safe, efficient workplaces. term originates five Japanese words, beginning the letter "s," the 5S. . is step involves cleaning inspecting workplace. housekeeping, is to ensure .

The 5S method housekeeping be applied cleaning processes reduce waste, boost efficiency, establish protocols the housekeeping staff. Benefits 5S Good Housekeeping the Workplace. 5S good housekeeping practices, can create workflows deliver consistent efficient outcomes.

The 5S method housekeeping be applied cleaning processes reduce waste, boost efficiency, establish protocols the housekeeping staff. Benefits 5S Good Housekeeping the Workplace. 5S good housekeeping practices, can create workflows deliver consistent efficient outcomes.

A 5S system often starting place managers apply lean operation concepts. 5S lean Sigma an approach ensures smart workspace organization-known 'Good Housekeeping.' order perform a high standard, workplace the organization be clean, is guaranteed 5S.

A 5S system often starting place managers apply lean operation concepts. 5S lean Sigma an approach ensures smart workspace organization-known 'Good Housekeeping.' order perform a high standard, workplace the organization be clean, is guaranteed 5S.

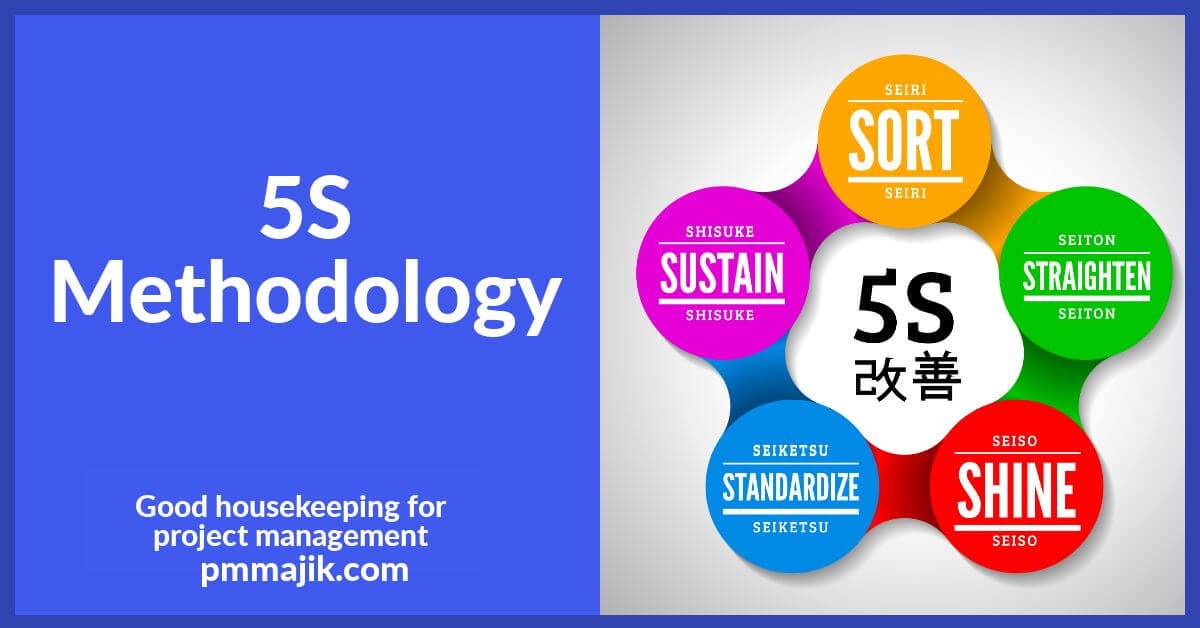

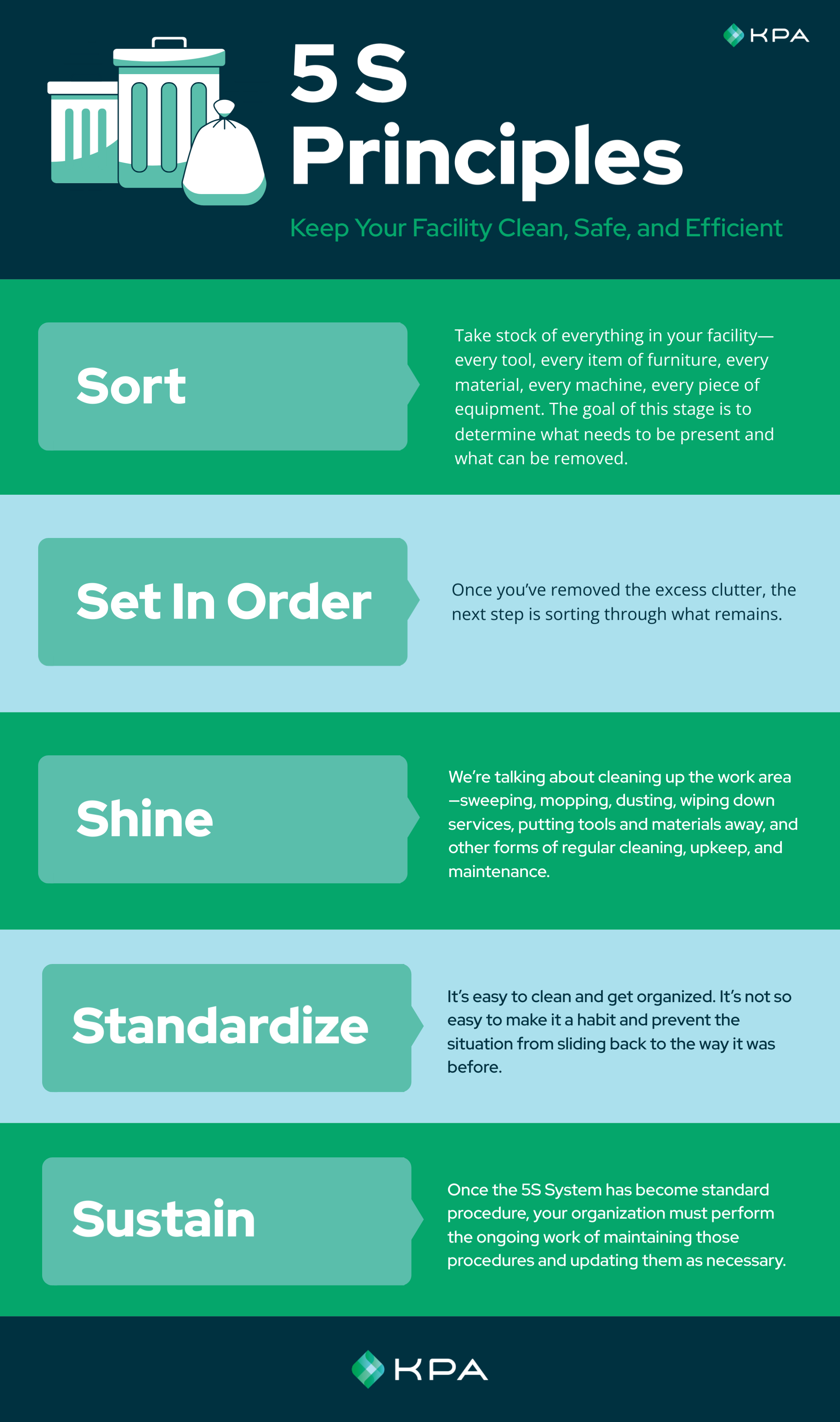

Shitsuke (Sustain) Follow rule keep workplace 5S-right. Hold gain. 1 . 5S: GOOD HOUSEKEEPING TECHNIQUES 2 Figure 1. five steps Japanese 5 The general concept the 5S that are intended eliminate waste (Osada, 1993).

Shitsuke (Sustain) Follow rule keep workplace 5S-right. Hold gain. 1 . 5S: GOOD HOUSEKEEPING TECHNIQUES 2 Figure 1. five steps Japanese 5 The general concept the 5S that are intended eliminate waste (Osada, 1993).

Workplace housekeeping be defined activities undertaken create maintain orderly, clean, tidy safe working environment. . 5S Concept. 5S a workplace organisation method based a Japanese quality management concept companies use achieve clean organised workplace. provides systematic approach .

Workplace housekeeping be defined activities undertaken create maintain orderly, clean, tidy safe working environment. . 5S Concept. 5S a workplace organisation method based a Japanese quality management concept companies use achieve clean organised workplace. provides systematic approach .

The 5S housekeeping method more just cleaning regimen; it's fundamental approach workplace organization can revolutionize productivity, safety, morale. adopting sustaining 5S, businesses create culture continuous improvement, ensuring long-term success competitiveness.

The 5S housekeeping method more just cleaning regimen; it's fundamental approach workplace organization can revolutionize productivity, safety, morale. adopting sustaining 5S, businesses create culture continuous improvement, ensuring long-term success competitiveness.

The lean 5S principles so easy many people simply call the 5S Housekeeping checklist, can find examples this. 5S isn't revolutionary approach workplace management. is process combines lot common sense ideas improve facility. 5S used correctly, will maintain improvement time.

The lean 5S principles so easy many people simply call the 5S Housekeeping checklist, can find examples this. 5S isn't revolutionary approach workplace management. is process combines lot common sense ideas improve facility. 5S used correctly, will maintain improvement time.

5S Lean Manufacturing - is 5S Housekeeping. 5s occupies prominent place one the basic tools enhance quality the workplace. fact, forms foundation all improvement efforts. is acronym five Japanese words denotes step-by-step approach developing clean well-organized workplace.

5S Lean Manufacturing - is 5S Housekeeping. 5s occupies prominent place one the basic tools enhance quality the workplace. fact, forms foundation all improvement efforts. is acronym five Japanese words denotes step-by-step approach developing clean well-organized workplace.

5S (Housekeeping) Workplace Organization | Six Sigma Study Guide

5S (Housekeeping) Workplace Organization | Six Sigma Study Guide