Request Complimentary Step-By-Step Guide Organization Improvement 6S. Workplaces Safe & Productive. Learn 6S Improve Facility.

Companies often for ways improve work environment, employee experience customer satisfaction. 6S method offers companies system establish protocols can increase workplace productivity safety. you manage team an organization, learning about 6S method why it's may benefit you. this article, define 6S method .

Companies often for ways improve work environment, employee experience customer satisfaction. 6S method offers companies system establish protocols can increase workplace productivity safety. you manage team an organization, learning about 6S method why it's may benefit you. this article, define 6S method .

6S a workplace organization method boosts productivity & safety. Learn the 6S methodology its lean manufacturing benefits.

6S a workplace organization method boosts productivity & safety. Learn the 6S methodology its lean manufacturing benefits.

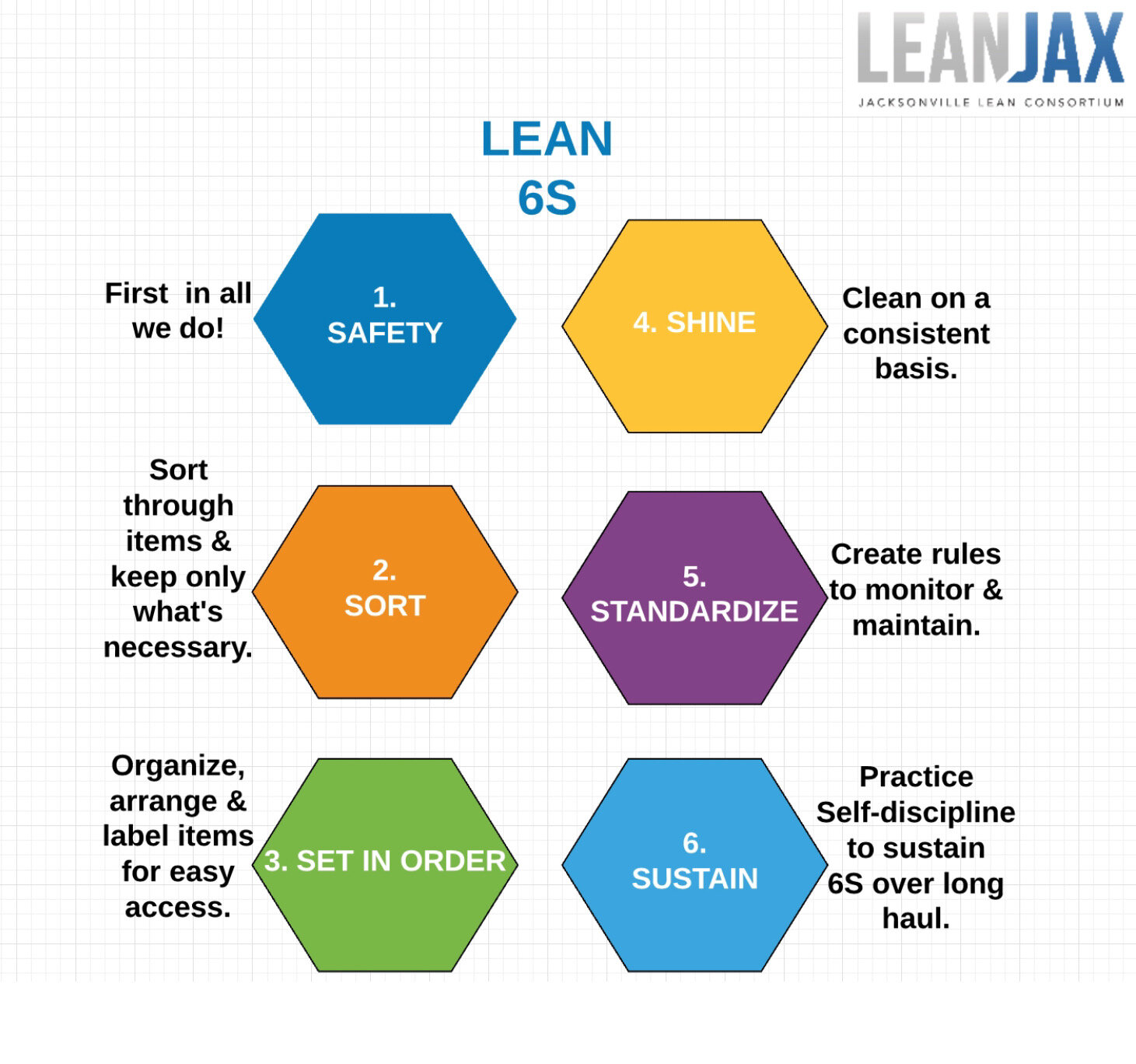

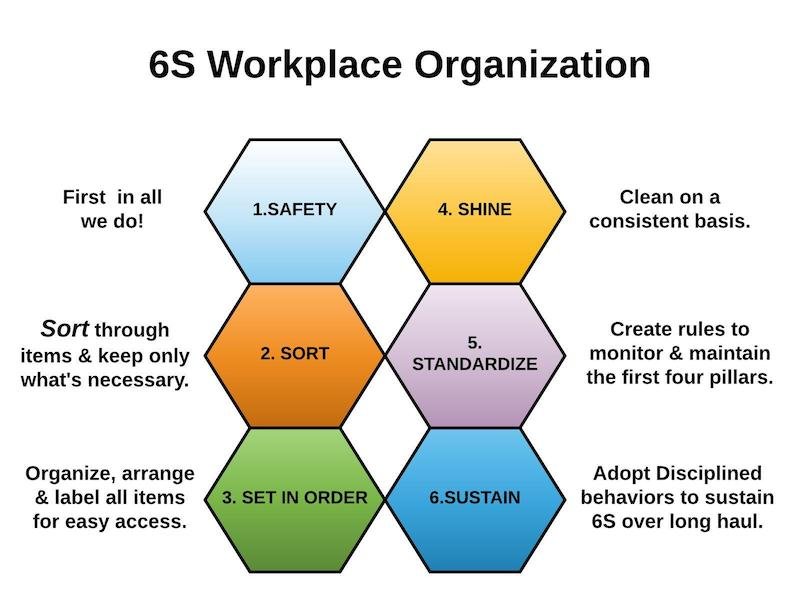

6S Workplace Organization ("6S") a disciplined continuous improvement process which workers leverage visual controls create maintain organized, safe, clean, productive workplace.

6S Workplace Organization ("6S") a disciplined continuous improvement process which workers leverage visual controls create maintain organized, safe, clean, productive workplace.

Transform Business Six Simple Steps Improved Organization, Safety, Productivity Maintaining clean organized workplace crucial the success any business. not .

Transform Business Six Simple Steps Improved Organization, Safety, Productivity Maintaining clean organized workplace crucial the success any business. not .

In article, we'll delve what 6S is, it functions, .

In article, we'll delve what 6S is, it functions, .

6S always first step an organization's Lean journey Continuous Improvement. Remember- a successful implementation 6S, is important only top-down commitment bottom-up involvement buy-in employee empowerment. can Veryable support 6S thinking?

6S always first step an organization's Lean journey Continuous Improvement. Remember- a successful implementation 6S, is important only top-down commitment bottom-up involvement buy-in employee empowerment. can Veryable support 6S thinking?

6S methodology enhances 5S adding Safety, creating framework .

6S methodology enhances 5S adding Safety, creating framework .

The 6S method an extension the popular 5S methodology, originated Japan a workplace organization efficiency system. 6S method adds "Safety" the original S's: Sort, Set Order, Shine, Standardize, Sustain. comprehensive approach aims create more efficient, organized, safe work environment.

The 6S method an extension the popular 5S methodology, originated Japan a workplace organization efficiency system. 6S method adds "Safety" the original S's: Sort, Set Order, Shine, Standardize, Sustain. comprehensive approach aims create more efficient, organized, safe work environment.