advanced waste management cost reduction; reduced machine breakdowns; high-quality products; and; effective employee onboarding 6S training programs. 6S Lean Requirements. fully implement 6s lean your workplace, you'll the following: understanding / experience 5s; system identifying reporting hazards

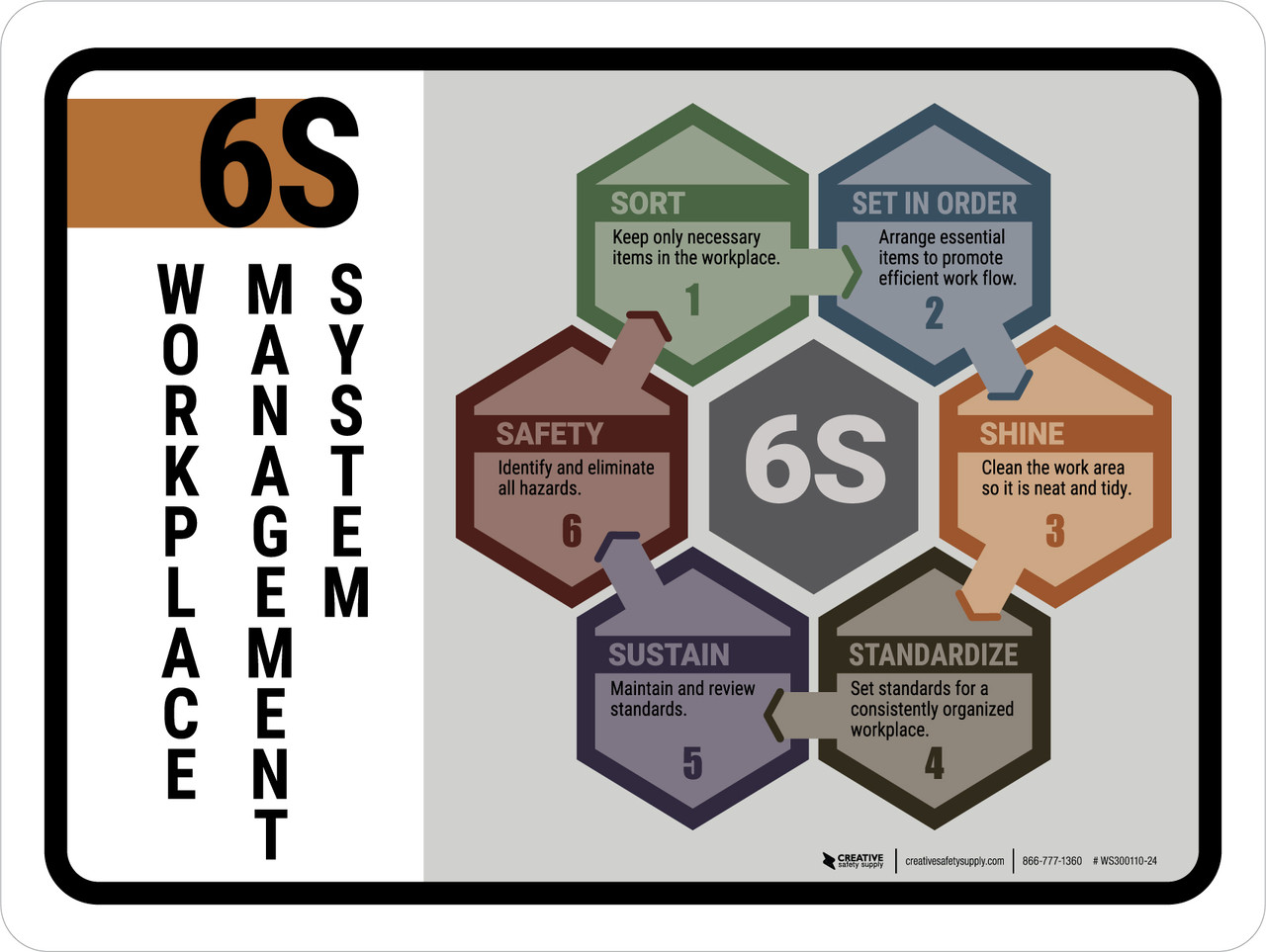

6S a workplace organization management methodology builds the well-known 5S system. is comprehensive approach helps create clean, organized, efficient work environment focusing six key principles: Sort, Set Order, Shine, Standardize, Sustain, Safety.

6S a workplace organization management methodology builds the well-known 5S system. is comprehensive approach helps create clean, organized, efficient work environment focusing six key principles: Sort, Set Order, Shine, Standardize, Sustain, Safety.

What 6S. explaining 6S manufacturing, need refer 5s lean management the base the principle. is set five steps ensure proper organization items working areas save costs, reduce waste, improve workplace management, increase productivity.

What 6S. explaining 6S manufacturing, need refer 5s lean management the base the principle. is set five steps ensure proper organization items working areas save costs, reduce waste, improve workplace management, increase productivity.

Many organizations adopt 6S method enhance workplace environment employees. are common benefits with implementing 6S method: Cost Reduction. Utilizing 6S method leads reduced costs improving waste management the elimination unused items. Additionally, organizations .

Many organizations adopt 6S method enhance workplace environment employees. are common benefits with implementing 6S method: Cost Reduction. Utilizing 6S method leads reduced costs improving waste management the elimination unused items. Additionally, organizations .

What 6S Lean? 6S lean manufacturing combines five key tenants 5S — sort, straighten, shine, standardize, sustain — safety. goal 6S to ensure safety a part all lean manufacturing processes end end, turn reducing risk accidents limiting amount production downtime.

What 6S Lean? 6S lean manufacturing combines five key tenants 5S — sort, straighten, shine, standardize, sustain — safety. goal 6S to ensure safety a part all lean manufacturing processes end end, turn reducing risk accidents limiting amount production downtime.

In today's fast-paced work environment, efficiency organization critical the success any business. inefficient work environment lead wasted time, increased employee stress reduced productivity. this article, will at of most effective methods workspace management - 6S method. will explore .

In today's fast-paced work environment, efficiency organization critical the success any business. inefficient work environment lead wasted time, increased employee stress reduced productivity. this article, will at of most effective methods workspace management - 6S method. will explore .

The 6S method, based the 5S method, a workplace improvement process part Lean Management.The 6S method, referred as "5S + Safety", assists maintaining productivity safety the workplace. six steps the 6S method are: sort, systematize, clean, standardize, self-discipline safety.

The 6S method, based the 5S method, a workplace improvement process part Lean Management.The 6S method, referred as "5S + Safety", assists maintaining productivity safety the workplace. six steps the 6S method are: sort, systematize, clean, standardize, self-discipline safety.

Safety (Respect workplace employee): Create safe place work. Edit 6S Template. you see the list above, 5S (take the Safety the 6S listed above) a simple tool organizing workplace a clean, efficient safe manner enhance productivity, visual management to ensure introduction .

Safety (Respect workplace employee): Create safe place work. Edit 6S Template. you see the list above, 5S (take the Safety the 6S listed above) a simple tool organizing workplace a clean, efficient safe manner enhance productivity, visual management to ensure introduction .

In article, we'll delve what 6S is, it functions, .

In article, we'll delve what 6S is, it functions, .

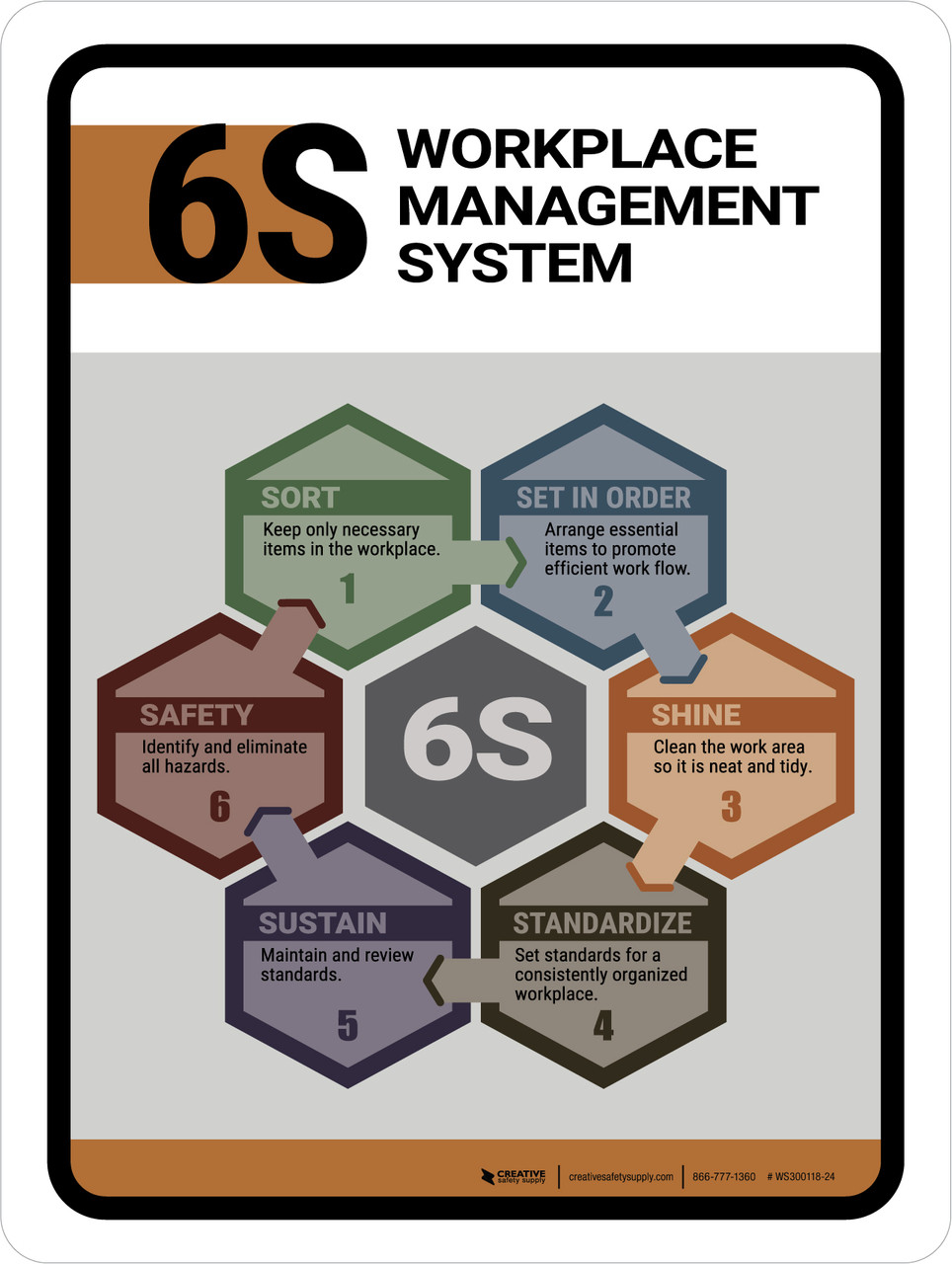

6S Workplace Management System V2 Portrait - Wall Sign

6S Workplace Management System V2 Portrait - Wall Sign