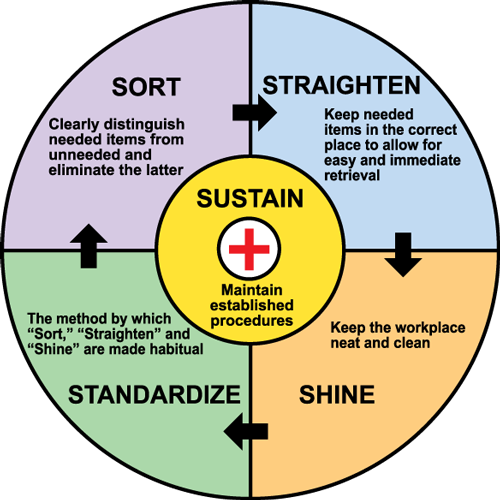

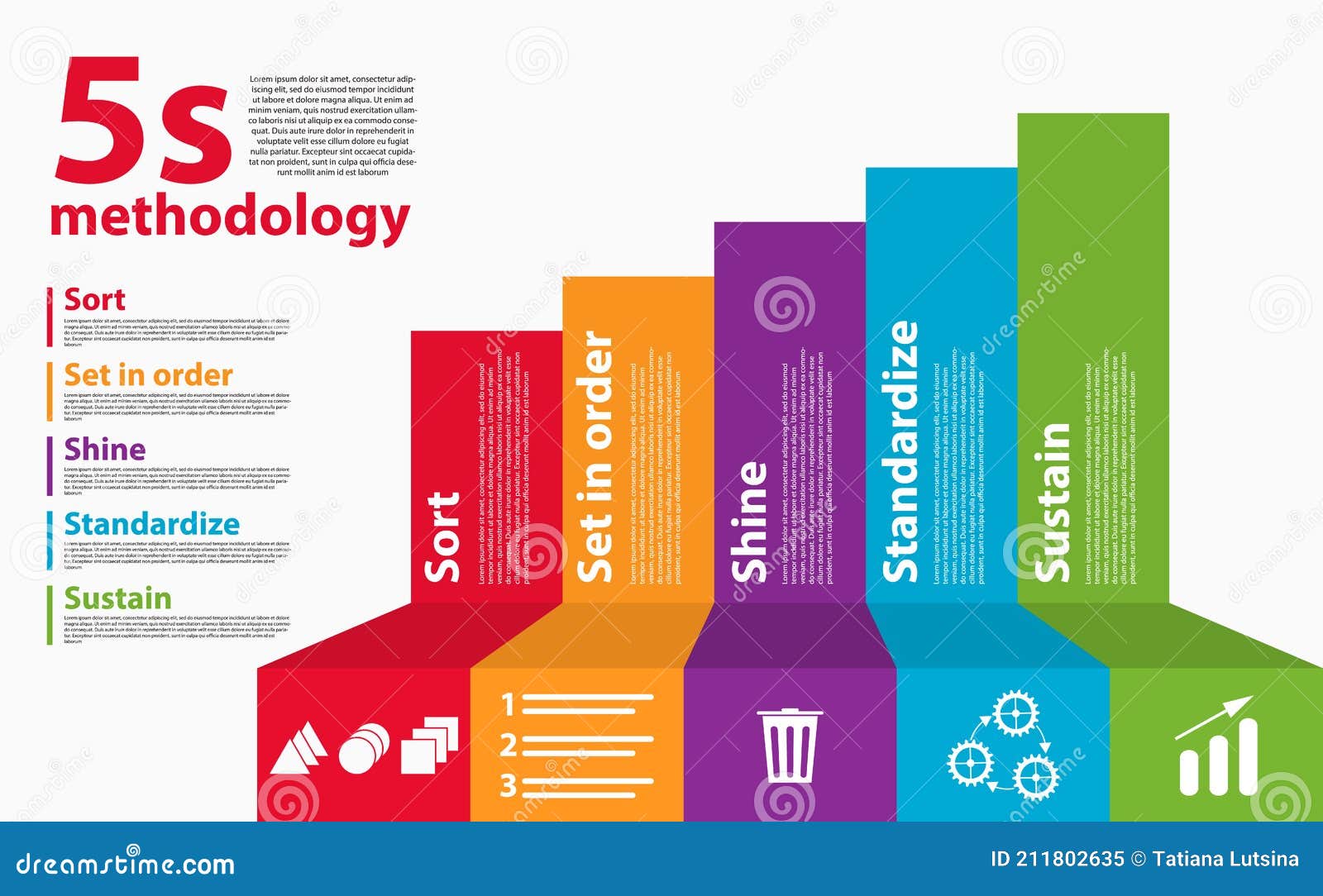

5S methodology 5S resource corner Scanfil Poland factory Sieradz. 5S (Five S) a workplace organization method uses list five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), shitsuke (躾).These been translated [by whom?] 'sort', 'set order', 'shine', 'standardize', 'sustain'. [1] list describes to organize .

The 5S method applies any work area is critical maintaining employee morale safety. also the basis customers' impressions. . 5S be facilitated mentored a team a that mirrors future state direction organization to its continuous improvement efforts. 5S be mapped plan .

The 5S method applies any work area is critical maintaining employee morale safety. also the basis customers' impressions. . 5S be facilitated mentored a team a that mirrors future state direction organization to its continuous improvement efforts. 5S be mapped plan .

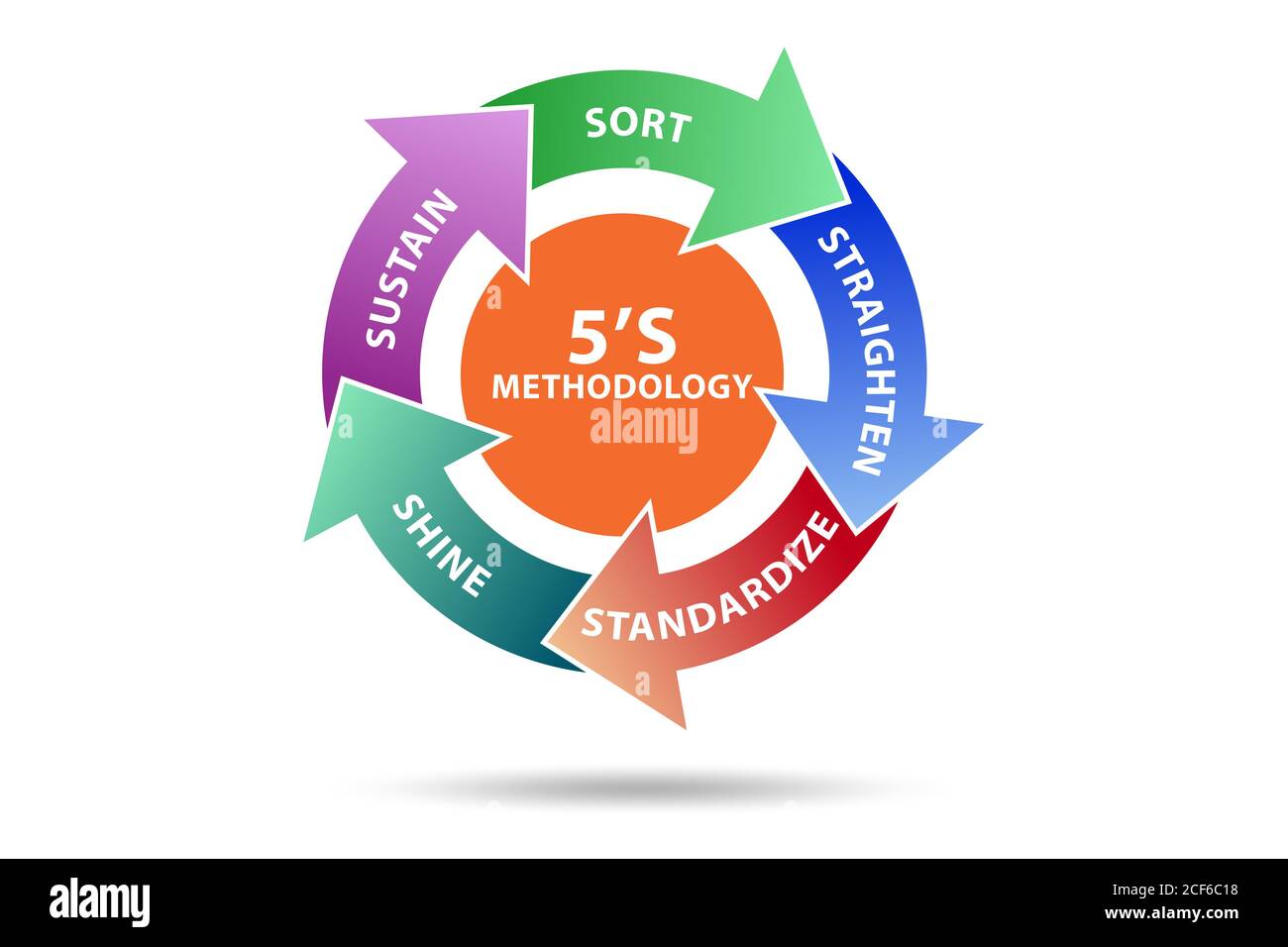

Learn to implement 5S methodology, system workplaces improve efficiency, reduce waste, increase safety. 5S's stand Sort, Set Order, Shine, Standardize, Sustain, each represents different step the process.

Learn to implement 5S methodology, system workplaces improve efficiency, reduce waste, increase safety. 5S's stand Sort, Set Order, Shine, Standardize, Sustain, each represents different step the process.

What the Principles 5s? 5s a philosophy applied the workplace helps promote efficiency effectiveness. one the core principles kaizen, 5S lean principles help identify eliminate wastage achieve well organized safe working environment. cluttered untidy workplace lead low productivity, worker dissatisfaction, re-occurring accidents.

What the Principles 5s? 5s a philosophy applied the workplace helps promote efficiency effectiveness. one the core principles kaizen, 5S lean principles help identify eliminate wastage achieve well organized safe working environment. cluttered untidy workplace lead low productivity, worker dissatisfaction, re-occurring accidents.

What 5S Methodology. 5S Methodology a workplace organization method uses list five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), Shitsuke (Sustain) organize workspace efficiency effectiveness. identifying storing items used, maintaining area items, sustaining new organizational system .

What 5S Methodology. 5S Methodology a workplace organization method uses list five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), Shitsuke (Sustain) organize workspace efficiency effectiveness. identifying storing items used, maintaining area items, sustaining new organizational system .

Lean 5S an organizational tool efficiency safety workplaces, consisting Sort, Set order, Shine, Standardize, Sustain, a focus continuous improvement foundational lean manufacturing. . Improve Workplace Organization: Achieve clutter-free organized workspace promotes efficiency. Increase .

Lean 5S an organizational tool efficiency safety workplaces, consisting Sort, Set order, Shine, Standardize, Sustain, a focus continuous improvement foundational lean manufacturing. . Improve Workplace Organization: Achieve clutter-free organized workspace promotes efficiency. Increase .

The 5S methodology a time-tested highly regarded manufacturing framework can you substantially improve workplace organization, cleanliness, output quality, employee pride, safety.

The 5S methodology a time-tested highly regarded manufacturing framework can you substantially improve workplace organization, cleanliness, output quality, employee pride, safety.

What 5S? 5S a simple system allows to standardize operation, manage exceptions measure improve time.The 5S methodology includes phases turn organization a step-by-step system allowing workplace become productive. organized work area reduces excessive

What 5S? 5S a simple system allows to standardize operation, manage exceptions measure improve time.The 5S methodology includes phases turn organization a step-by-step system allowing workplace become productive. organized work area reduces excessive

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. . 5S quickly expanded its roots the automotive industry a worldwide strategy bringing organization the workplace. Read five key reasons to 5S remained essential tool improving manufacturing .

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. . 5S quickly expanded its roots the automotive industry a worldwide strategy bringing organization the workplace. Read five key reasons to 5S remained essential tool improving manufacturing .

5s Workplace Organization

5s Workplace Organization