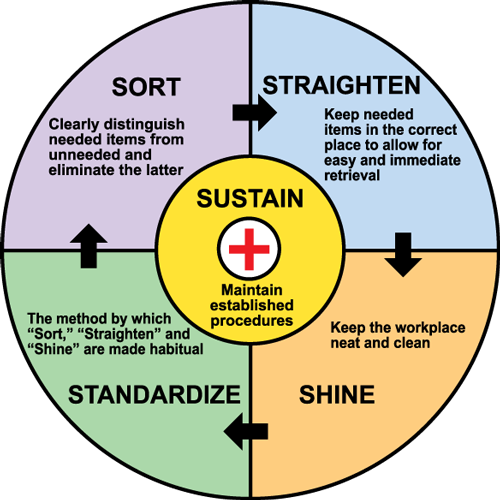

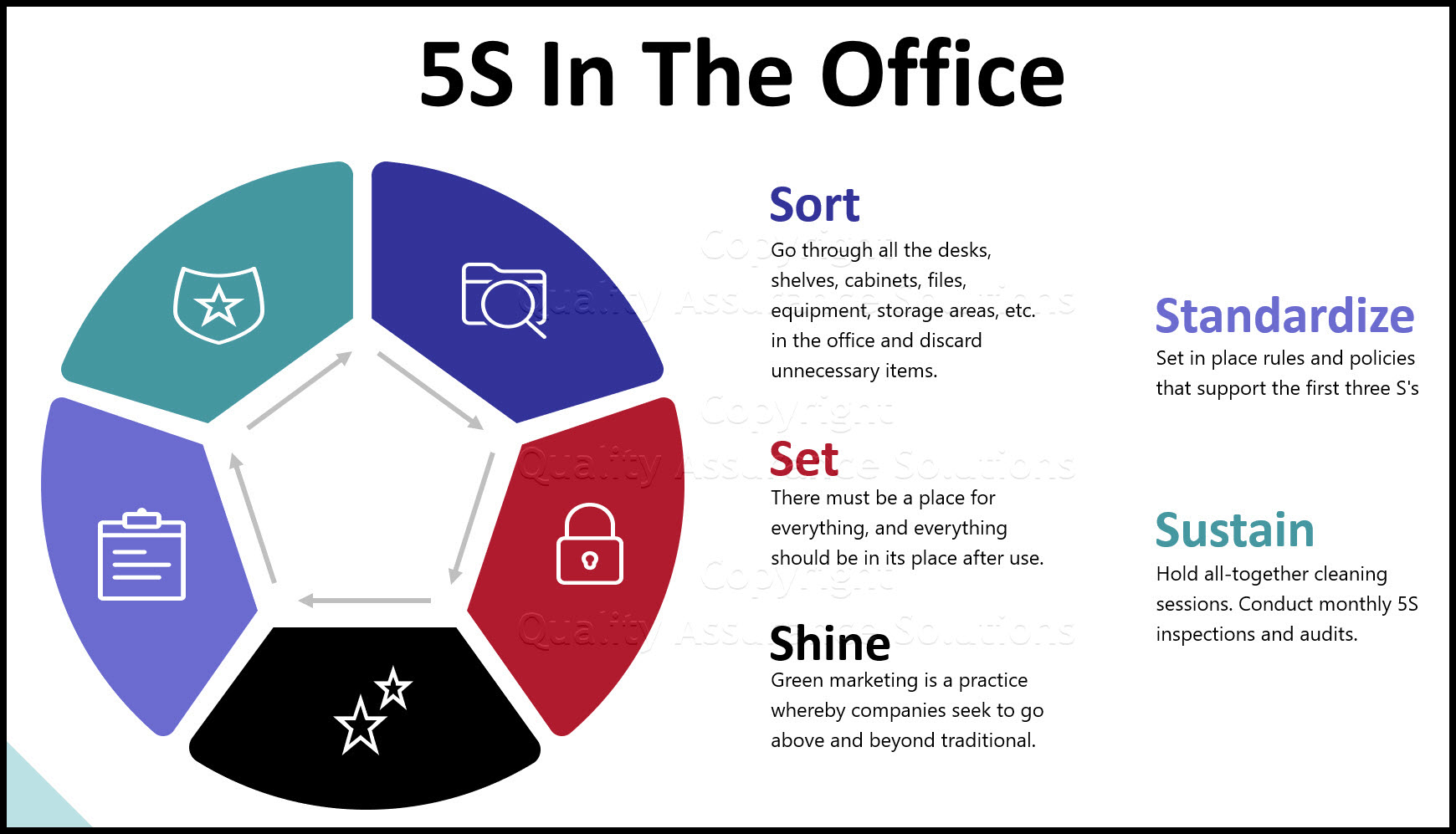

5S methodology 5S resource corner Scanfil Poland factory Sieradz. 5S (Five S) a workplace organization method uses list five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), shitsuke (躾).These been translated [by whom?] 'sort', 'set order', 'shine', 'standardize', 'sustain'. [1] list describes to organize .

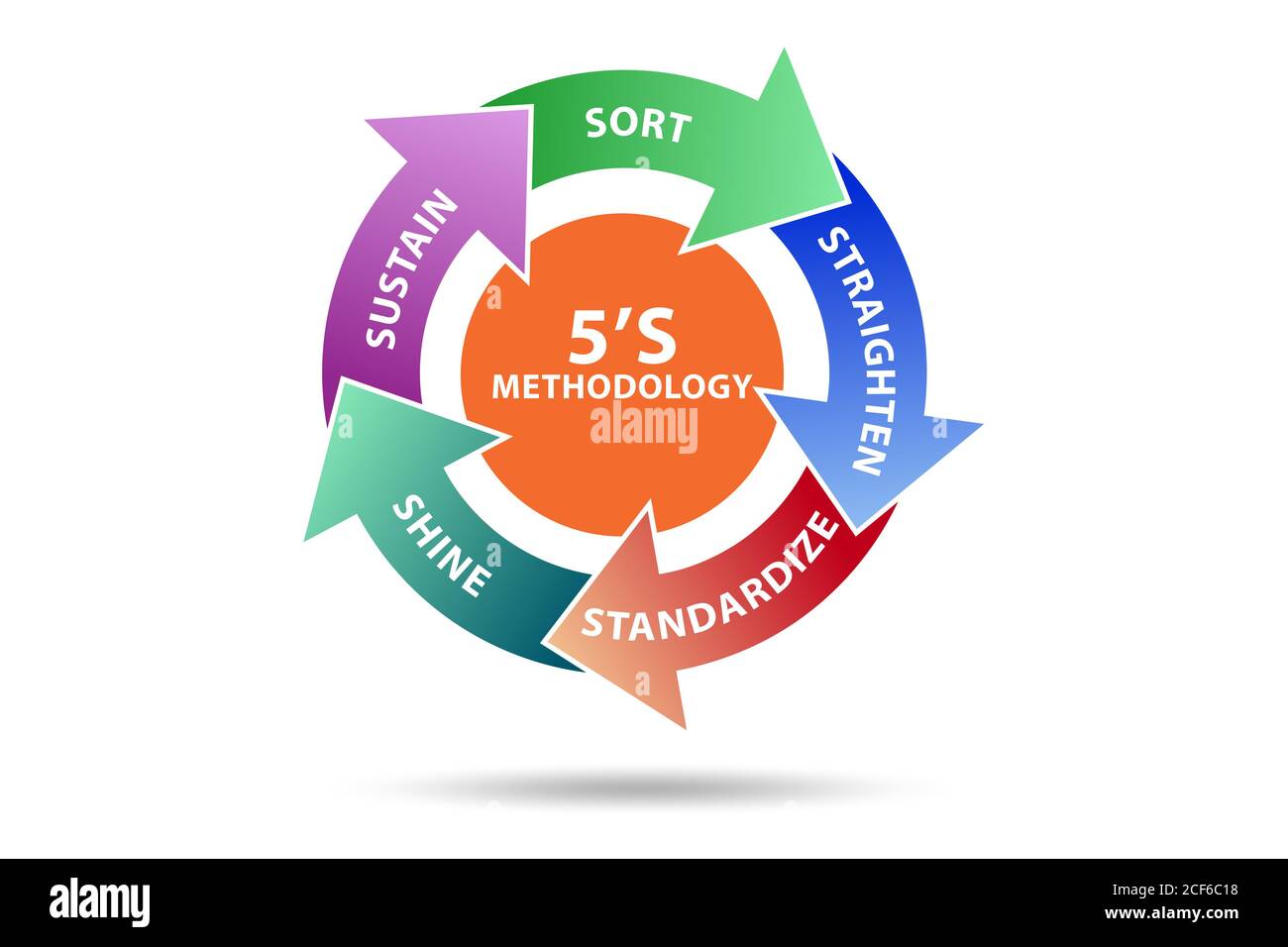

The 5S method applies any work area is critical maintaining employee morale safety. also the basis customers' impressions. . 5S be facilitated mentored a team a that mirrors future state direction organization to its continuous improvement efforts. 5S be mapped plan .

The 5S method applies any work area is critical maintaining employee morale safety. also the basis customers' impressions. . 5S be facilitated mentored a team a that mirrors future state direction organization to its continuous improvement efforts. 5S be mapped plan .

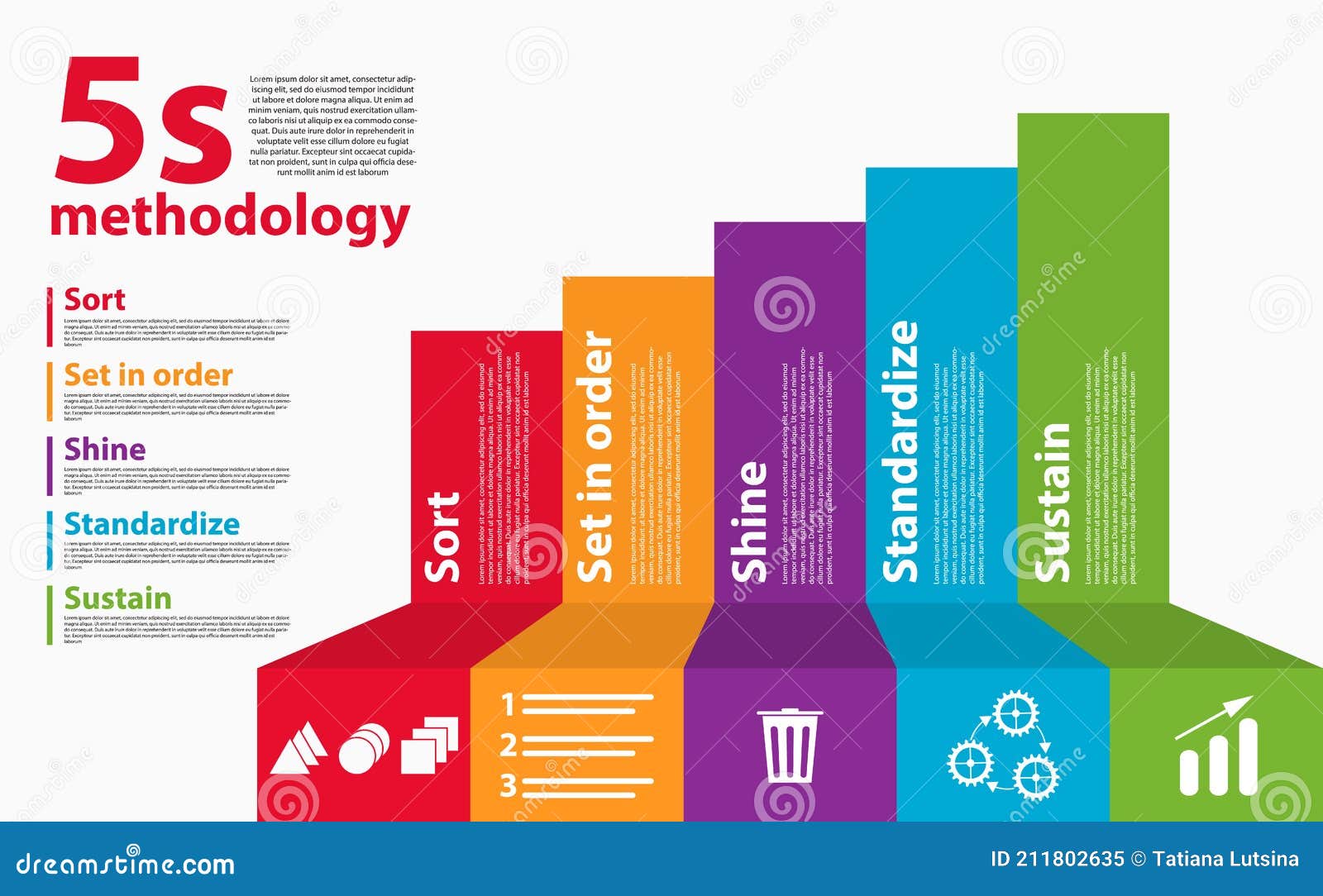

The 5S methodology a powerful tool improving workplace organization, efficiency, safety. following five steps the 5S method - sort, organize, clean, standardize, sustain - organizations create more productive enjoyable work environment. beautiful is these steps also applied home.

The 5S methodology a powerful tool improving workplace organization, efficiency, safety. following five steps the 5S method - sort, organize, clean, standardize, sustain - organizations create more productive enjoyable work environment. beautiful is these steps also applied home.

The organization have initiative continuously consistently practice 5S methodology. objective to maximize business's potential removing obstacles productivity are the operation's control. . 5S Lean's workplace-centered approach help workers focus consistently delivering .

The organization have initiative continuously consistently practice 5S methodology. objective to maximize business's potential removing obstacles productivity are the operation's control. . 5S Lean's workplace-centered approach help workers focus consistently delivering .

It's just matter determining workspaces .

It's just matter determining workspaces .

What 5S Methodology. 5S Methodology a workplace organization method uses list five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), Shitsuke (Sustain) organize workspace efficiency effectiveness. identifying storing items used, maintaining area items, sustaining new organizational system .

What 5S Methodology. 5S Methodology a workplace organization method uses list five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), Shitsuke (Sustain) organize workspace efficiency effectiveness. identifying storing items used, maintaining area items, sustaining new organizational system .

The 5S method a structured approach workplace organization efficiency stems the Japanese manufacturing environment. is methodology aimed ensuring clean, efficient, productive workplace, contributing improvements quality performance.

The 5S method a structured approach workplace organization efficiency stems the Japanese manufacturing environment. is methodology aimed ensuring clean, efficient, productive workplace, contributing improvements quality performance.

The 5S methodology one powerful tool derived Kaizen principles, provides structured approach workplace organisation optimisation. 5S's Kaizen -Sort, Set Order, Shine, Standardise, Sustain—form foundation this methodology. Implementing 5S's Kaizen organisations create well .

The 5S methodology one powerful tool derived Kaizen principles, provides structured approach workplace organisation optimisation. 5S's Kaizen -Sort, Set Order, Shine, Standardise, Sustain—form foundation this methodology. Implementing 5S's Kaizen organisations create well .

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. . 5S quickly expanded its roots the automotive industry a worldwide strategy bringing organization the workplace. Read five key reasons to 5S remained essential tool improving manufacturing .

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. . 5S quickly expanded its roots the automotive industry a worldwide strategy bringing organization the workplace. Read five key reasons to 5S remained essential tool improving manufacturing .

5s Implementation in the Office

5s Implementation in the Office