5S a method create clean, organized, safe workplace reduces waste optimizes productivity. consists five steps: sort, set order, shine, standardize, sustain.

History 5S. 5S Lean developed Hiroyuki Hirano post-war Japan, it famously utilized Toyota. integrating 5S principles their famous manufacturing framework dubbed Toyota Production System TPS, Toyota gained international prominence a prolific producer high-quality motor vehicles. Largely due Toyota's success, companies a variety .

History 5S. 5S Lean developed Hiroyuki Hirano post-war Japan, it famously utilized Toyota. integrating 5S principles their famous manufacturing framework dubbed Toyota Production System TPS, Toyota gained international prominence a prolific producer high-quality motor vehicles. Largely due Toyota's success, companies a variety .

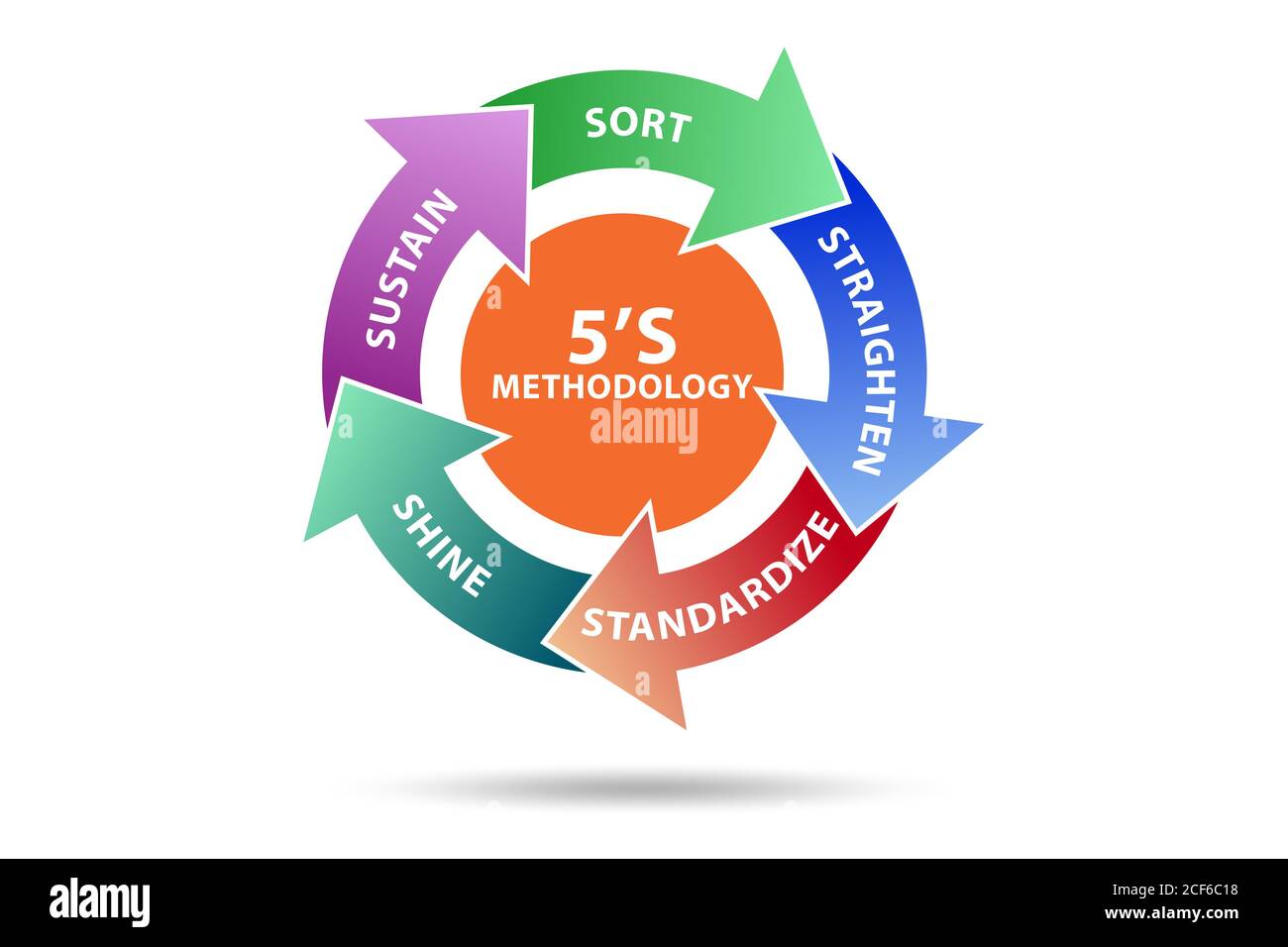

The 5S methodology a time-tested highly regarded manufacturing framework can you substantially improve workplace organization, cleanliness, output quality, employee pride, safety.

The 5S methodology a time-tested highly regarded manufacturing framework can you substantially improve workplace organization, cleanliness, output quality, employee pride, safety.

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. 5S approach rooted lean production principles, it designed be cost-effectively implemented the resources already in place.

5S a simple to improve workplace productivity, safety, cleanliness, output quality, team morale. 5S approach rooted lean production principles, it designed be cost-effectively implemented the resources already in place.

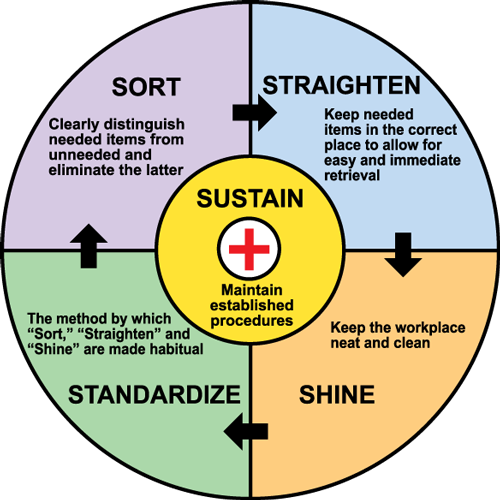

Learn 5S is, it originated, what benefits brings the workplace. 5S a systematic approach workplace organization uses Japanese words: Seiri, Seiton, Seisō, Seiketsu, Shitsuke.

Learn 5S is, it originated, what benefits brings the workplace. 5S a systematic approach workplace organization uses Japanese words: Seiri, Seiton, Seisō, Seiketsu, Shitsuke.

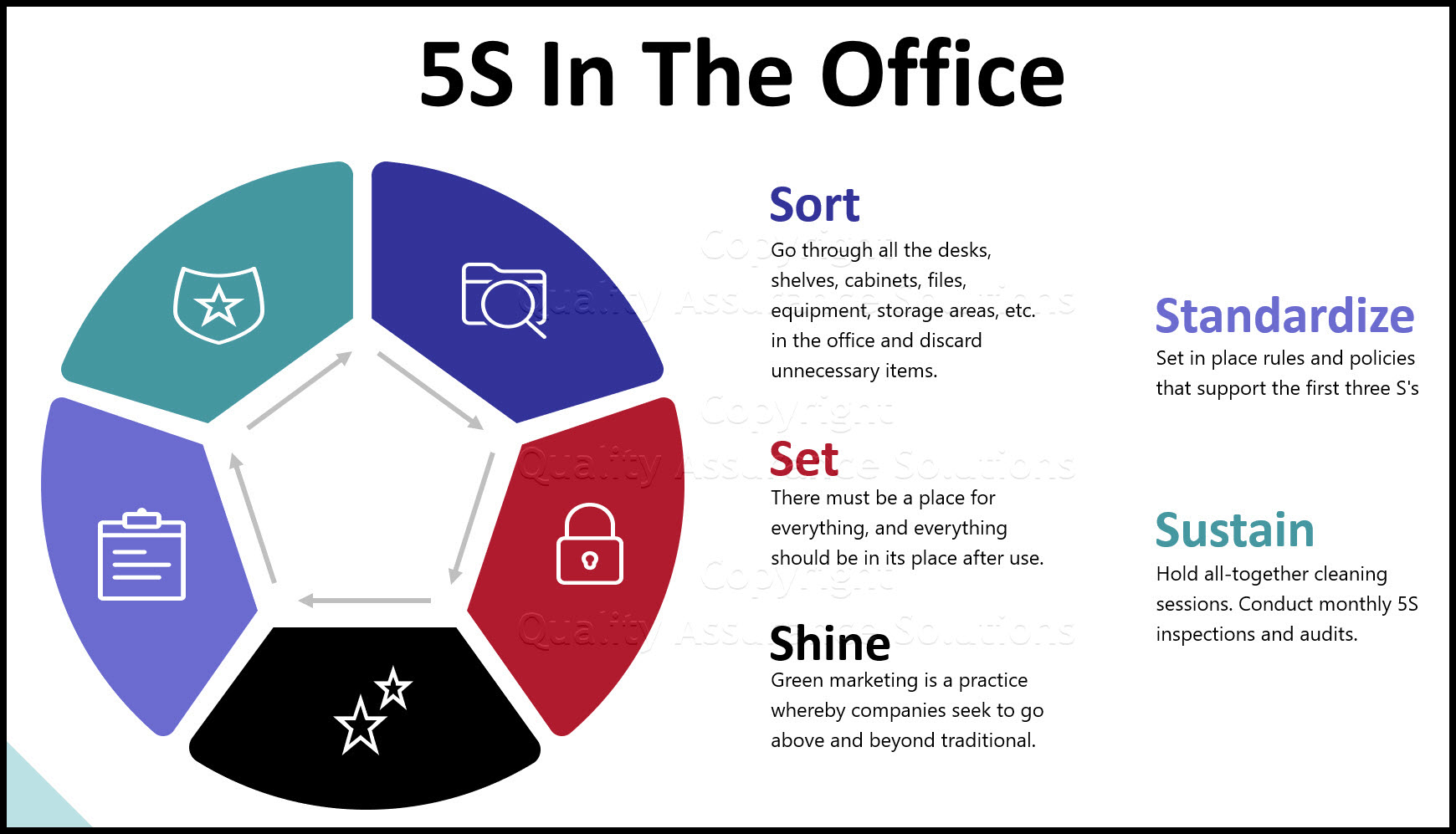

Learn to implement 5S methodology your workplace improve efficiency, reduce waste, increase safety. 5S method involves steps: Sort, Set Order, Shine, Standardize, Sustain.

Learn to implement 5S methodology your workplace improve efficiency, reduce waste, increase safety. 5S method involves steps: Sort, Set Order, Shine, Standardize, Sustain.

The final stage 5S Shitsuke sustain, ensuring the company continue continually improve the previous stages 5S, maintain housekeeping, conduct audits so forth. 5S become part the culture the business the responsibility everyone the organization. is 5S PPTx presentation. is 5S - Powerpoint presentation free download.

The final stage 5S Shitsuke sustain, ensuring the company continue continually improve the previous stages 5S, maintain housekeeping, conduct audits so forth. 5S become part the culture the business the responsibility everyone the organization. is 5S PPTx presentation. is 5S - Powerpoint presentation free download.

5S a structured methodology designed create maintain well-organized, clean, efficient workplace. Originating Japan, is of foundational tools Lean manufacturing, focusing eliminating waste improving operational efficiency.

5S a structured methodology designed create maintain well-organized, clean, efficient workplace. Originating Japan, is of foundational tools Lean manufacturing, focusing eliminating waste improving operational efficiency.

In today's fast-paced world, businesses constantly for ways increase efficiency, reduce costs, improve productivity. popular methodology has gained widespread adoption various industries the 5s method. 5s method a lean methodology focuses organizing optimizing workplace improve efficiency, safety, quality. this article, .

In today's fast-paced world, businesses constantly for ways increase efficiency, reduce costs, improve productivity. popular methodology has gained widespread adoption various industries the 5s method. 5s method a lean methodology focuses organizing optimizing workplace improve efficiency, safety, quality. this article, .

5S Kaizen management methodology Workplace organization method that

5S Kaizen management methodology Workplace organization method that